Scheduled dates are computed in order to be able to plan deliveries, receptions and so on. Depending on the habits of your company, Vorlik automatically generates scheduled dates via the scheduler. The Vorlik scheduler computes everything per line, whether it’s a manufacturing order, a delivery order, a sale order, etc. The dates that are computed are dependent on the different leads times configured in Vorlik.

Configuring lead times

Configuring lead times is an essential move in order to compute scheduled dates. Lead times are the delays (in term of delivery, manufacturing, …) promised to your different partners and/or clients. Configuration of the different lead times are made as follows:

On a product level

Supplier lead time:

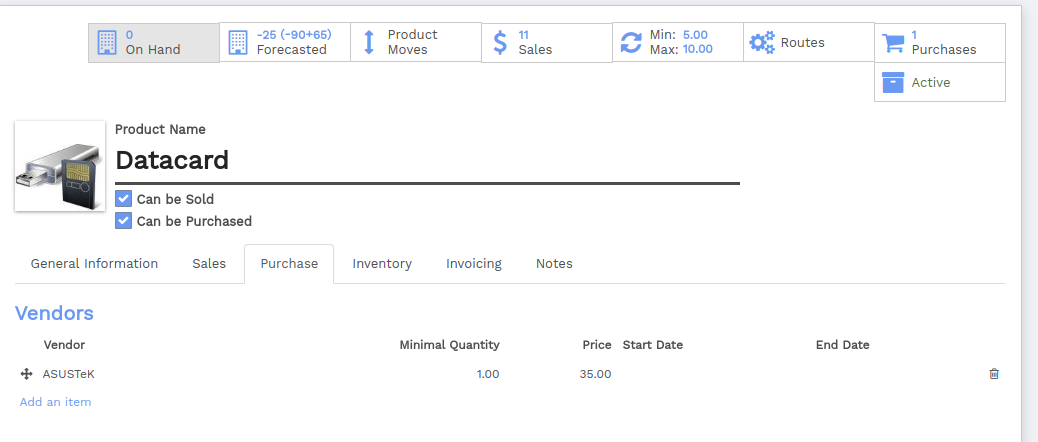

The supplier lead time is the time needed for the supplier to deliver your purchased product. To configure the Supplier lead time select a product (from the Purchase module, go to ), and go in the Inventory tab. You will have to add a Vendor to your product in order to select a supplier lead time.

Tip

It is possible to add more than one vendor per product and thus different delivery lead times depending on the vendor.

Once a vendor is selected, click on it to open its form and indicate its delivery lead time.

Note

In this case security days have no influence, the scheduled delivery days will be equal to: Date of the purchase order + Delivery Lead Time.

Customer lead time

The customer lead time is the time needed to get your product from your store/warehouse to your customer. It can be configured for any product. Simply select a product (from the Sales module, go to ), and go into the Sales tab to indicate your customer lead time.

On route level

The internal transfers due to the movement of stocks can also influence the computed date.

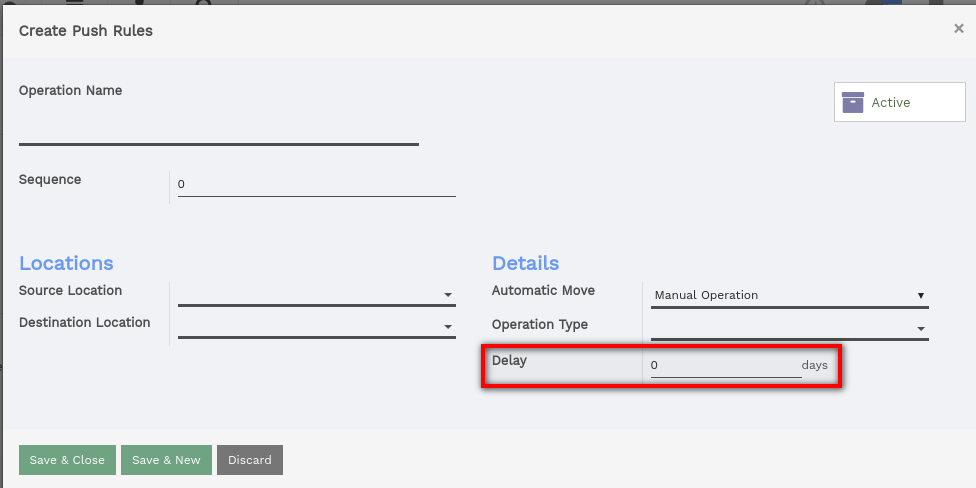

The delays due to internal transfers can be specified in the Inventory module when creating a new push rule for a new route.

Note

Read the documentation What is a push rule? to learn more.